Delivering Value Through All Phases of the Ship Life Cycle

Our Capabilities

Comprehensive Ship Design and Engineering

The core of our technical offering is our multidisciplinary ship design and engineering capability. We provide support in all ship design phases:

Concept Design

Preliminary Design

Contract Design

Production Design

We employ technical professionals with expertise across all relevant ship design disciplines:

Naval Architecture

Mechanical Engineering (Power, Propulsion, HVAC, Auxiliary, and Mission Systems)

Electrical Engineering

Electronics Engineering

Structural Engineering

Tridentis provides expertise and support through the entire ship acquisition life cycle:

Concept and Requirements Development

Acquisition

Production

Life Cycle Sustainment

Modernization and Service Life Extension

Inactivation and Disposal

New Ship Design

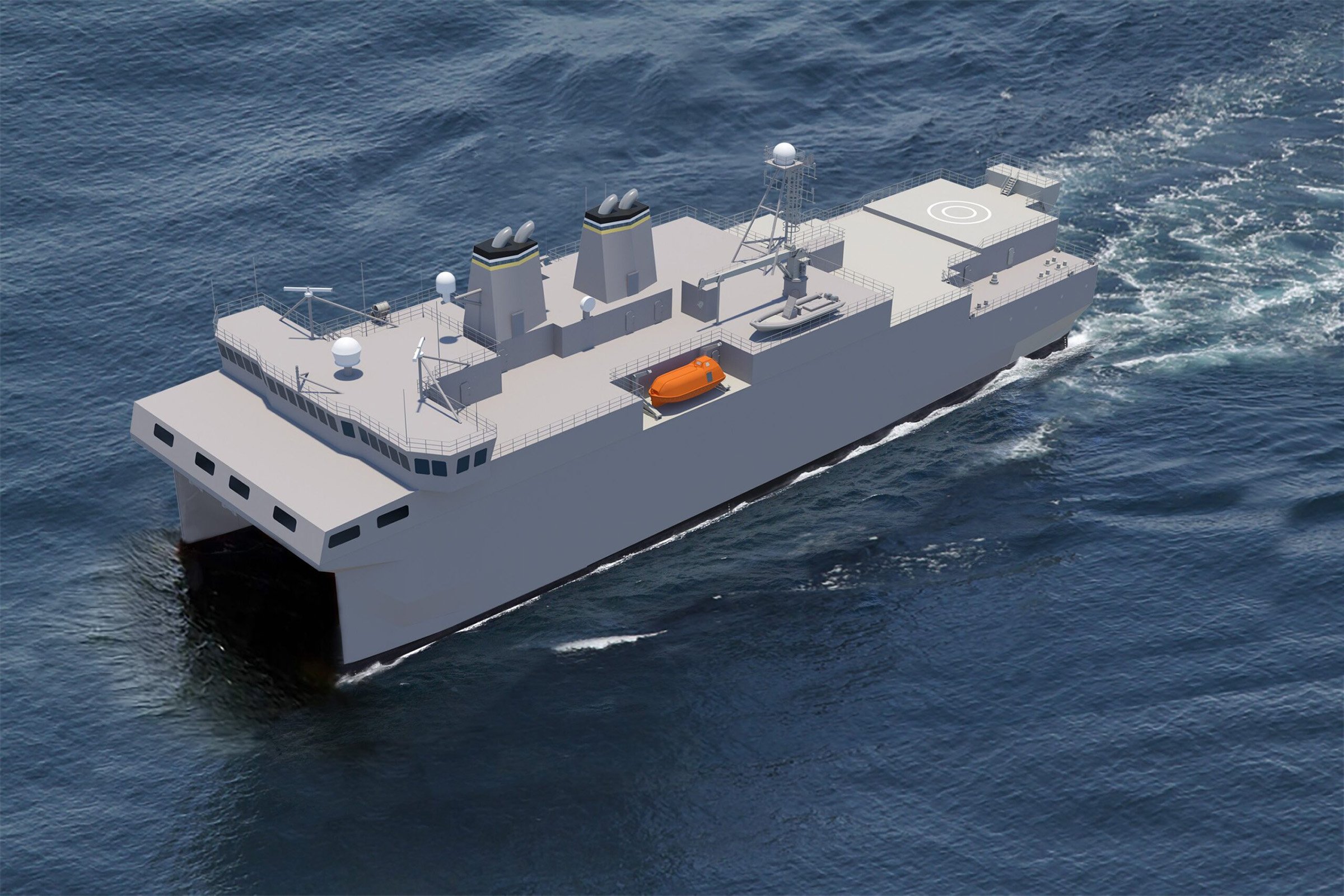

From early concept development and trade studies through modeling and production engineering, Tridentis has the experience and capability to be an effective lead design agent across all naval architecture and ship design disciplines.

We are prepared to work as an integral team member for shipbuilders throughout a new ship design project. Because shipbuilders vary widely in the engineering tools and resources at their disposal, not to mention their construction methodology, we tailor our approach to most effectively integrate our team into the overall project.

For current and prospective shipowners, our focus is being a trusted, independent partner and advisor through the entire project. We establish a clear vision of the owner’s goals and requirements, conduct analyses, convey professional advice, and deliver quality work products. Our support helps owners make informed decisions on trade-offs, and allows them to tap our wealth of industry connections to select the ideal builder and manage a successful construction and delivery effort.

Tridentis is experienced in traditional spiral and 2D ship design methods, as well as modern integrated 3D design, and can develop design products to any format required by the customer or shipbuilder. Whether for shipbuilders or shipowners, our new ship design agent support emphasizes producibility, requirements compliance, and deliverable quality.

In-Service Modernization and Repair

Tridentis brings vast experience supporting ship modernization, repair, refurbishment, refit, and other forms of existing ship modification.

This work typically begins with a shipcheck to assess and document the current condition of the ship. Tridentis routinely leads shipchecks in locations throughout the U.S. and worldwide, including CONUS and OCONUS locations. We are able to quickly mobilize small and large teams for either quick single-day shipchecks or more extended, multi-week efforts. Our experienced shipcheck teams know how to efficiently work through ship spaces to mark up drawings and gather necessary information to guide subsequent engineering efforts. We are also experienced in utilizing 3D scanning technology to document a space in support of 3D design efforts, or simply to complete the shipcheck as rapidly as possible.

When existing conditions and project requirements are understood, Tridentis employs the full suite of engineering disciplines to proceed with the design effort. This includes engineering analyses and trade studies to weigh best value options and guide decision-making. It also includes the development of work packages, such as Ship Installation Drawings (SIDs) and Ship Change Documentation (SCDs), that provide the drawings and supporting technical data necessary to guide the installation or modification effort.

Tridentis support for ship modernization and repair efforts emphasizes accuracy of existing conditions information, safe and efficient work aboard the ship, and high quality of ship change documentation. Our work packages are complete, clear, and in conformance with all applicable standards and requirements, as demonstrated through little to no return comments or backfixes. Our goal is to deliver 100% complete packages upon first submittal.

Program Office Support

Tridentis has exceptional knowledge and experience as a contractor supporting U.S. Navy, U.S. Coast Guard, and other Government fleet program offices. These offices have unique and complex responsibilities and requirements to support acquisition and life cycle sustainment for shipbuilding programs across program management, business, financial, technology development, systems engineering, ship design, production, test and evaluation, post-delivery, integrated logistics, and inactivation domains. Successful execution of these diverse governmental responsibilities involves broad-ranging contractor support.

As the next-generation ship design and engineering contractor based in the DC area, Tridentis is prepared to serve in Prime Contractor and subcontractor roles for program office requirements. We are committed to delivering flexible, adaptable, efficient, responsive, and knowledgeable program and technical support across all disciplines and ship acquisition phases. Our goal is to help maximize the productivity, efficiency, and accountability of portfolio programs and the efforts of the capable uniformed and civilian personnel working in these offices.

Specialized Engineering Analysis

Tridentis has the tools and expertise to conduct nearly any type of engineering or naval architecture analysis. In numerous cases, our customers have relied on our analytical capabilities to understand physical conditions, develop or optimize designs, evaluate alternatives and trade spaces, and validate the appropriateness of or conformance to requirements. We employ both conventional and advanced tools and techniques to understand complex or vexing problems and identify practical solutions.

Examples of the types of analyses we can provide include, but are not limited to:

Finite Element Analysis (Local and Whole Ship)

Shock Analysis

Computational Fluid Dynamics

3D Scanning, Modeling, and Digital Twin

3D Kinematic Physics Based Simulation

Ship Motions and Seakeeping Analysis

Resistance, Powering, and Propulsion Analysis

Energy and Emissions Analysis

Electric Power Load Analysis

Fault Current Analysis and Protective Device Study

Intact and Damage Stability Analysis

Incident Response and Forensic Analysis

Regulatory Requirements and Class Standards Studies

Small Tasks and Shipyard Support Services

Tridentis is well suited to support small tasks and emergent requirements that may be required by shipowners, shipyards, and support contractors. Such tasking may include drydocking and mooring calculations, stability documentation, engineering assessments and solutioning, as-built or record drawing production, ship condition assessment, or shipchecks.

Our employment philosophy emphasizes hiring professionals with diverse, multidiscipline capability, and can-do attitudes. Combined with competitive pricing, accurate estimating, and efficient contracting processes, we are able to provide our engineering and technical expertise for nearly any type or size of task.

While other firms may pass over small tasks as not worth their time, none is too small for Tridentis to quickly quote and deliver to high quality and customer satisfaction.

Integrated Logistics Support

Learning lessons from prior generations, modern shipbuilding programs, especially those for the U.S. Government, have sought to address maintenance and sustainment requirements earlier in the ship acquisition life cycle. As the complexity and performance expectations of vessels and shipboard systems continues to advance, so too must supportability keep pace.

Tridentis draws upon the depth of our engineering and technical knowledge to deliver comprehensive support for the wide range of Integrated Logistics Support (ILS) requirements applicable to modern shipbuilding. We deliver ILS support in both acquisition and sustainment phases, including supply, provisioning, maintenance planning, configuration management, tools and parts support, test equipment support, and related documentation support.

We are comfortable and experienced working within relevant fleet owner enterprise systems, and understand how to apply broader principles and best practices to the specific ILS processes and systems a fleet owner may utilize.